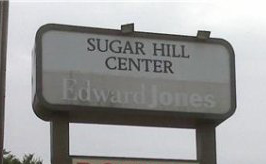

A Faded Sign

There are many types of materials that we use in the sign industry, with each having a specific usage or application. There does, however, exist a sort of “Grey-area” when it comes to exactly what quality and/or material-type you should use when building a custom sign. Typically we choose materials based on where and how long the sign will be in place. Many outdoor signs are built using shorter durability vinyls and less expensive plastics in order to save money, but this practice can lead to a sign that lasts significantly less time and breaks down faster than one that costs a bit more, but uses the highest quality materials.

There are basically two types of print and cut vinyl apart from the specialty stuff such as reflective or high-metallics. Intermediate vinyl, or calendared, and High-quality, or cast. Calendared vinyl is available as print or cut, and is generally rated to last about 4-6 years outdoor. Cast material is a thinner and more pliable product, and is rated between 8-10 years of outdoor durability. These ratings are simply guidelines and factors such as sun position and climate can greatly affect the overall lifespan.

On the other side of the sign is the actual panel, or substrate. Common substrates for signage includes MDO wood, coroplast, acrylic, aluminum and hybrids of two or more materials fused together. Choosing the right substrate can be confusing too, and often times a cheaper material is used to cut costs, but in the long run, a consumer could end up paying more due to a need to replace the sign sooner. A very common example that we run across often is the use of acrylic panels. Typically used in shopping centers with a lighted cabinet behind it, acrylic, or the brand name lexan, is used when a stronger and more durable material called polycarbonate should be used, epecially in the northeast US climate. Acrylic is a very strong material, but in an outdoor setting, there are some major drawbacks. When compared to poly, acrylic is not as impact resistant and can actually shatter when struck. Polycarbonate, however is nearly 100x stronger and can withstand very high impact without failing. Also, acrylic is only available in 8′ lengths also, which means a large sign needs to be split into two pieces, creating an ugly seam. Even with all the drawbacks to using acrylic, it is still widely used due to the lower cost.

At Boyd Geyer Sign Corp., we pride ourselves on using the right materials for the job, and although it may cost a bit more ,the quality will show through for years. Make sure you know what you are getting on your next sign project, or contact us for a free estimate.